SOLUTION FOR INGOT CASTING

ECO-PROJECT

PRODUCTION SINCE 1958

ISOPAN - LITEPAN - EXOPAN - HARDPAN

PLATES AND COMPOSED FEEDING HEADS

THE MATERIAL IS PRODUCED ACCORDING TO THE DRAWING OF MOLDS. HIGHLY REFRACTORY, EXOTHERMIC OR INSULATING MATERIAL DESIGNED TO REDUCE PIPING AND SEGREGATION OF A KILLED STEELS. A RANGE OF PRODUCTS MADE UP OF SECTORS AND WEDGES.

Benefits:

- Material is light in weight, strong and thermic resistant, suitable for all sizes of moulds

- Tapered corner pieces compensate for slight mould differences, giving good wedging action in all circumstances

- Tha shape of tiles and the wedging action of corner pieces reduce gaps between the assembly and the mould

- After use, the material forms a powdery or partially sintered residue which removes cleanly from the ingot.

EXOCAP

ANTI-PIPING COMPOUND BOARDS

INSULATING OR EXOTHERMIC BOARDS, COMPLEMENTARY TO HOT TOPS, PRODUCED ACCORDING TO THE SPECIFIC DRAWINGS.

A VALID ALTERNATIVE TO REPLACE EXOTHERMIC OR INSULATING POWDER.

Benefits:

- Complete covering of steel surface

- Environmental advantages because the powder is not used

- Low fume of low toxicity

- The cover is placed in advance, so no necessity of worker’s operation

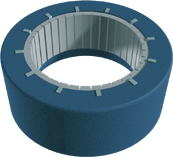

ISOFLEX - LITFLEX - EXOFLEX - HARDFLEX

INSULATING AND EXOTHERMIC FLEXIBLE CHAINS

FLEXIBLE CHAINS MADE OF BRICKS IN DIFFERENT KIND OF MATERIAL

SUITABLE FOR ROUND HOT TOP WITH DIAMETER BIGGER THAN 500 MM.

Benefits:

- Multiple use for replacement of many monolithic hot tops

- Reduced storage place

- Immediate availability for any possible changes of ingot molds

- High insulation, valid alternative to RCF materials

- Easy assembling thanks to flexibility and suspension hooks

- Dimension variation of sectors for better performance

- Possibility of easier application by gluing on the mold with COLLATEX FLEX

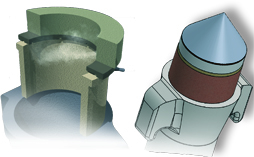

VOLUMIX

MONOLITHIC AND SECTOR HOT TOPS

INSULATING AND EXOTHERMIC HOT TOPS DESIGNED ACCORDING TO SPECIFIC DRAWINGS IN ONE PIECE OR IN SECTOR FOR BIG DIAMETER OR AT CUSTOMER’S REQUEST.

Benefits:

- Bending radius designed to be fit to the ingot mold

- Easy and simple application. necessary for high productivity

- High insulation and feeding performance

- Hot top surface free from residual material

- Easy to cut

- Friability of residual material after casting, it is not necessary to clean the

hot top

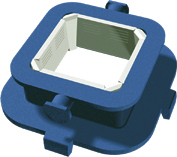

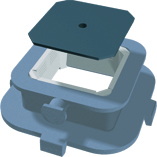

PROFLUX e CONEX

FLUX PROTECTION RINGS, ARGON CONNECTIONS AND SLAG SEPARATORS

PROFLUX: IS A MULTI-SECTOR MATERIAL FOR THE PROTECTION OF THE MOLTEN METAL FLOW DURING THE OPERATIONS OF INGOT MOLD CASTING.

CONEX: IS DESIGNED IN ORDER TO AVOID THE FALL OF CHROMITE POWDERS AND SLAGS IN THE FEEDING INGOT CHANNELS DURING THE OPENING OF THE SLIDING LADLE BOX.

Benefits:

- Suitable with argon connection and distribution sustem inside Protection of the molten metal flow from oxidation during casting

- Avoided discharges and metal jets out of the casting column

- Protection of the bottom of ladle

COLLATEX - REFRAX

VERY SPECIAL VETRIFICANT CERAMIC COMPOUND FIRECLAY FOR GATING SYSTEM

COLLATEX 25 IS A BI-COMPONENT VETRIFICATION TO SEAL THE REFRACTORY TUBES TO THE INGOT MOLD PLATES.

Benefits:

- Very strong connection of all bricks

- No gas emission during the melting

- Increase the thermal and mechaninc resistance of refractory

- After casting the channels of plate are clean, it is not necessary maual operations